Case Studies & Testimonials

Case Study: End-to-End Services from Fabrication to Shipping with Exceptional Service and Craftsmanship

An international corporate services and equipment firm contracted CB Fabricating to provide end-to-end fabrication, finishing, packing, and shipping services for some of its key product line. Due to the highly visible use of the products in corporate settings, the highest levels of attractive finish, construction quality, and production consistency are required to maintain the client’s reputation among its clientele. With these strict quality requirements come frequent high volume, cost-sensitive orders.

Working closely with the client from the outset of the contract, CB Fabricating developed new turnkey fabrication processes for each product to ensure all client requirements are met with each and every order. Initial design optimization consultations helped minimize material waste (and cost) and increase fabrication speed. Continuous quality monitoring at all stages of production through delivery is provided for every order, week after week, month after month. This ongoing commitment to quality and customer service has given our customer confidence in putting CB Fabricating manufactured products front and center in its offering for its corporate services clients.

“The team at CB Fabricating took on our project that was outside of their normal day-to-day scope of business. They have done a phenomenal job with the ongoing execution of managing our complex product line. Their service, expertise, and craftsmanship are exceptional. They have been a pleasure to work with.”

— Chuck R., corporate services and equipment client senior manager

Case Study: Design for Manufacturing Saves Time and Cost

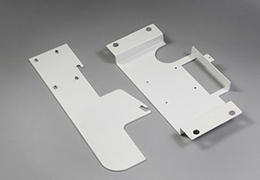

CB Fabricating was contacted by a management and design company with a concept for a product that required sheet metal parts. We were able to exceed their expectations and provide more than just the necessary parts. We provided consultation on concept development, sheet metal design, design for manufacturability, and design for serviceability. We participated through the entire design cycle from concept design to part specification to material procurement to fabrication and even through final assembly. We were able to supply our customer with a cost-effective and easy-to-manufacture product that could be brought to market in a fraction of the anticipated time.

“I was very pleased to discover that CB Fabricating was willing to take my concept and turn it into reality. What I ended up with was far more than I expected. I ended up with a reliable, capable, and highly qualified partner. They have been committed to my success from the beginning of our first project and have helped in every aspect of development.”

— Kiosk Manufacturer

Case Study: Competitive Pricing and Excellent Customer Service

A local metal parts manufacturer relies on CB Fabricating to support their overflow needs. When this manufacturer is unable to produce parts in the time-frame needed due to capacity or other issues, we are able to produce the needed parts. The companies have established mutual trust, allowing them to work together to the benefit of both companies. Not only does the manufacturer trust that CB Fabricating will deal fairly and honestly, they also know that the fabricated parts will be of the utmost quality and delivered on time.

“CB Fabricating responds to quotes in a timely manner with competitive pricing. Their capabilities and quality make them a viable choice for our fabricating needs. Their customer service is excellent and prompt.”

— Metal Parts Manufacturer

Case Study: Flexibility and Efficiency to Meet Fluctuating Customer Needs

CB Fabricating has been able to maintain long-standing relationships with many of our customers. For example, a local grain conditioning company has been a regular customer since our business began in 2007. Their business operates on a demanding schedule with changes in needs occurring sometimes on a daily basis. Our flexibility has enabled us to adjust to their fluctuating demands. In addition, they have been pleased with our ability to use their raw materials in an efficient manner and to minimize scrap.

“Doing business with CB Fabricating is like having an extension of our own facility without the problems of personnel and machinery investment and upkeep.”

— Agricultural Building Manufacturer

Contact CB Fabricating for Information Request a Quote